MANUFACTURE

World pattern, frontier technology, craftsmanship

—— RUNXINTANG ——

A. Production capacity: 700 million granules/year

B. Specification: Scope of 1~20g Form: Single-row machine, multiple-row machine, three-side seal, four-side seal, back seal (sawtooth and right angle) and rounded special-shaped bag

C. Main production equipment: TCM powerful crushing unit, superfine grinding unit, continuous dynamic heat reflux extraction unit, multi-function extractor, double-effect concentration unit, ultrasonic heat reflux extraction unit, centrifugal spray unit, granulating system (tank mixing + swing, rapid wet process, rapid rotation, one-step granulating, dry granulating), mixing system (pyramid mixing, three-dimensional mixing), granule racking machine (single-row machine, multiple-row machine, three-side seal, four-side seal, back seal (sawtooth and right angle) and rounded special-shaped bag) and hot shrinkable film machine

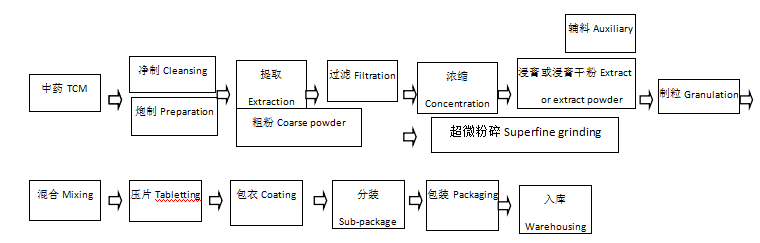

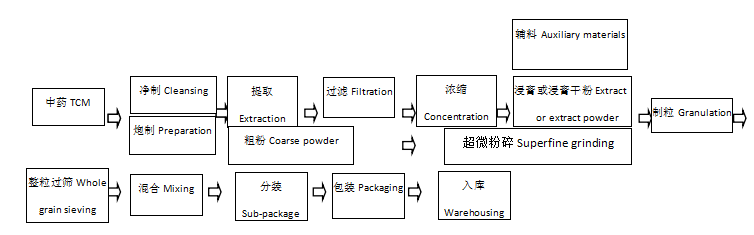

D. Process flow:

Beverage

A. Production capacity: Mold-formed bottle: 100 million bottles/year; tube-type bottle: 1.2 billion pieces/year; back seal special-shaped bag: 100 million bags/year; block bottom bag: 60 million bags/year; zip-top can: 120 million cans/year

B. Specification: Bottled: 10ml 20ml 30ml 50ml 150ml 250ml; packaged with back seal special-shaped bag: 5ml 10ml 15ml; block bottom bag: 30ml 40ml 50ml; zip-top can: (two-piece can and three-piece can)

C. Main production equipment: TCM powerful crushing unit, continuous dynamic heat reflux extraction unit, multi-function extractor, double-effect concentration unit, ultrasonic heat reflux extraction unit, high-speed centrifugal unit, liquid mixing system, full-automatic flow production line of glass (bottle arrangement - bottle washer - drying - sterilization - potting), full-automatic ampoule sterilization leak detector, light detector, high-speed labeling machine of oral liquid, multi-column plastic bag filling machine, horizontal special-shaped bag packaging machine, water bath ventilation and sterilization cabinet, full-automatic production line of zip-top can (bottle arrangement - bottle washer - potting - sterilization - leak inspection - packaging) and hot shrinkable film machine

D. Process flow:

Tea bag

A. Production capacity: 65 million bags/year

B. Specification: Scope of 1~5g Form: Three-side seal

C. Main production equipment: TCM powerful crushing unit, superfine grinding unit, continuous dynamic heat reflux extraction unit, multi-function extractor, double-effect concentration unit, ultrasonic heat reflux extraction unit, centrifugal spray unit, granulating system (tank mixing + swing, rapid wet process, rapid rotation, one-step granulating, dry granulating), mixing system (pyramid mixing, three-dimensional mixing), granule racking machine (three-side seal) and hot shrinkable film machine

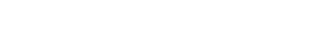

D. Process flow:

Tablets

A. Production capacity: 700 million pieces/year

B. Specification: 0.3g 0.4g 0.5g 0.6g 0.7g 0.8g 0.9g 1.0g 1.2g 1.5g 1.8g 2.0g

C. Main production equipment: TCM powerful crushing unit, superfine grinding unit, continuous dynamic heat reflux extraction unit, multi-function extractor, double-effect concentration unit, ultrasonic heat reflux extraction unit, centrifugal spray unit, granulating system (tank mixing + swing, rapid wet process, rapid rotation, one-step granulating, dry granulating), mixing system (pyramid mixing, three-dimensional mixing), high-speed tablet press (special-shaped), efficient coating pan, full-automatic bottle sub-package flow production line of bottle unscrambler, dryer, piece counting machine, cap screwing machine, thermal sealing machine and labeling machine, full-automatic aluminum plastic - aluminum - aluminum plastic blister machine, pillow-type packaging machine and hot shrinkable film machine

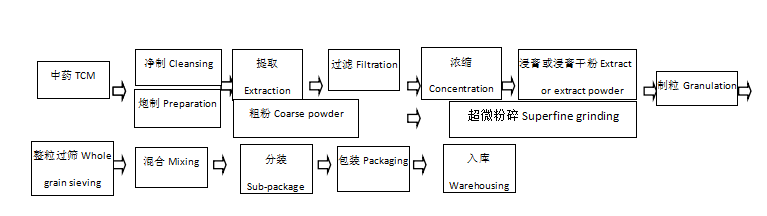

D. Process flow: